XENOY

Applications

- Automobile and truck

- Crockery and dietary

- Defense, security, protection

- Electric and electronic

- Healthcare

- Industry and tools

- Sport and hobbies

Transformation

- Extrusion

- Injection

Normes

- ISO 10993

- Pharmacopée USP XXI class VI

- UL 94 V0

Description

Technical datasheets

Contact

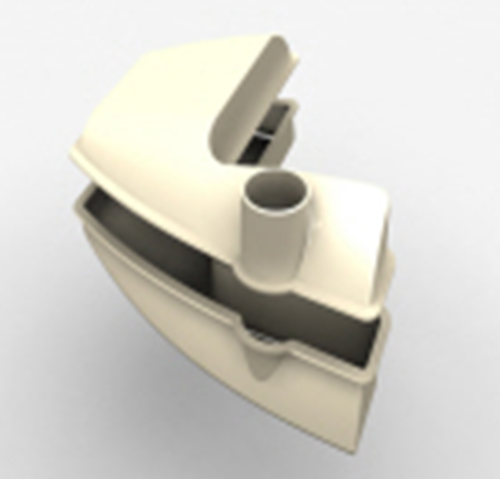

The XENOY alloy is a blend of semi-crystalline polyester (typically polybutylene terephthalate, PBT, or polyethylene terephthalate, PET) and polycarbonate (PC). The XENOY resin family offers good chemical resistance, great impact resistance even at low temperatures, heat resistance, and outstanding aesthetic and flow characteristics.

XENOY alloys offer outstanding performance in applications that are exposed to harsh conditions, or that require a high degree of toughness.

New XENOY iQ* resins are created with polybutylene terephthalate (PBT)-based polymers derived from 60% post-consumer plastic waste, consuming less energy and yielding less carbon dioxide (CO2) in their manufacturing than traditional resins.

Properties

- Chemical resistance and low temperature impact strength

- UV stabilized

- UV aging resistance, dimensional stability

- Available for injection and extrusion

- Grades loaded with glass fibers from 10 to 30%